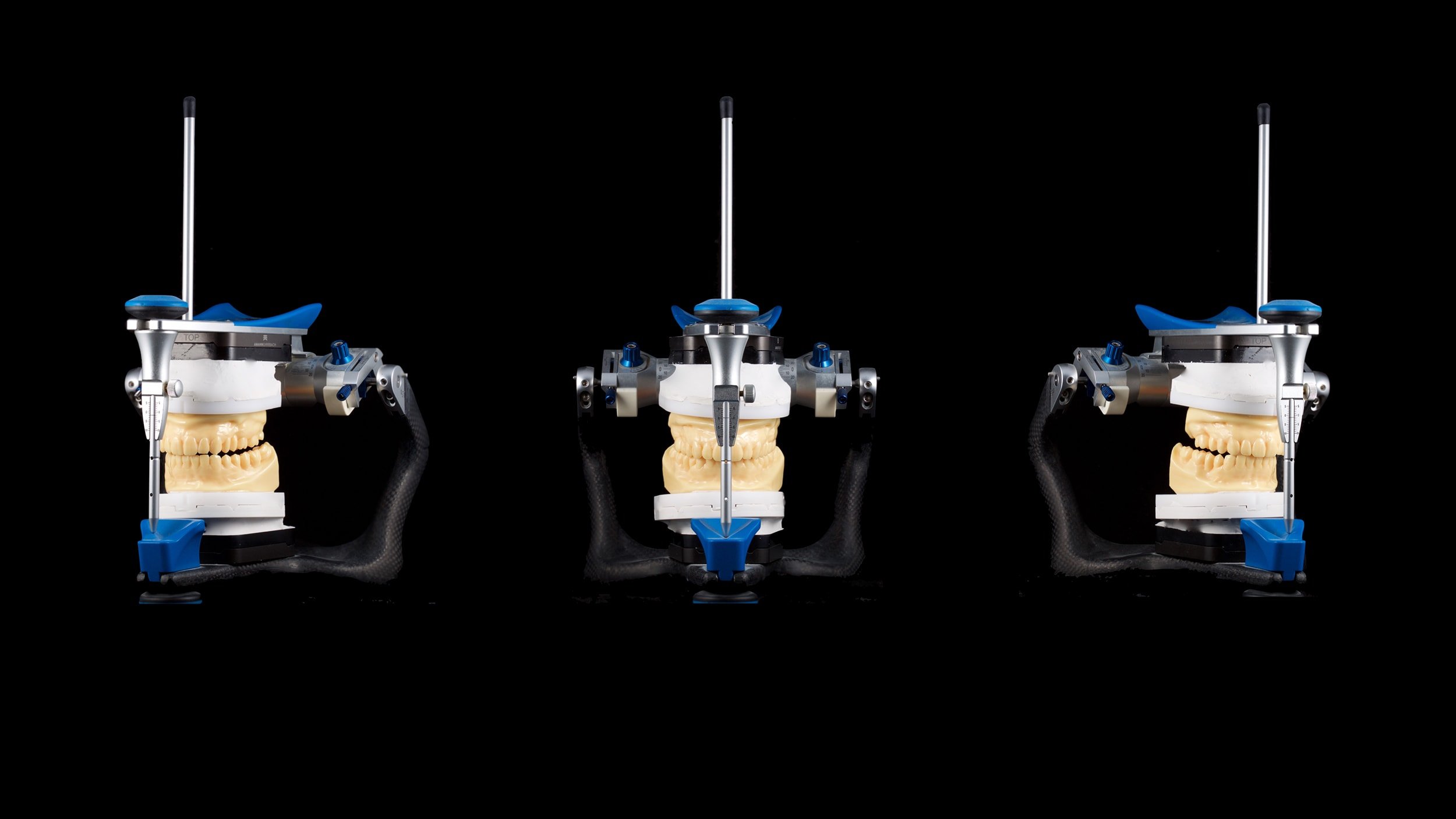

For us to be able to make one of our work models, we use one of the most precise methods called GIROFORM. By using giroform one can be in complete control of the expansion of the work model, so the precision of our work models is 99,92% by specially testing the plaster material.

Such precise models we place in the articulator and are in complete control of their position by doing certain procedures which will assure we are 99,97% precise.

Afterwards, the proces of fine drilling follows if necessary, as to achieve a 100% precision level. Only then, everything is ready to be scanned and transferred into the software.

The basis of each case is preparation like this one and it’s called model management.

Before starting certain cases, we use the DSD (Digital Smile Design) way of planning our work. In order to be able to use DSD, we need high-quality photographs of specific angles of the patient's face and teeth and, of course, a comprehensive understanding of aesthetics and aesthetic parameters.

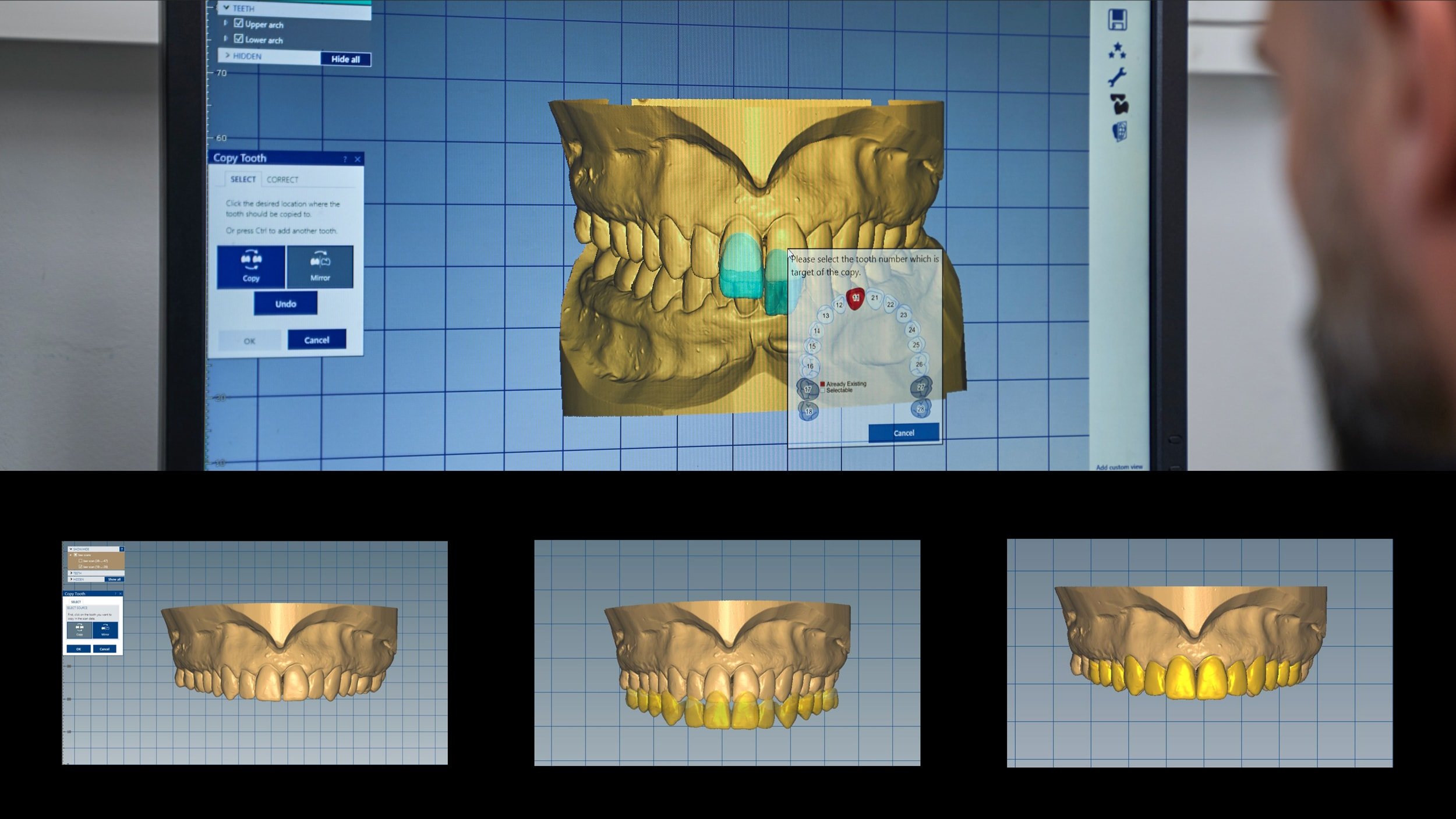

Every case made in our laboratory is based exclusively and without exception on a copy of the natural tooth shapes that we make by entering them into the software.

We always copy the patient's existing teeth, if possible.

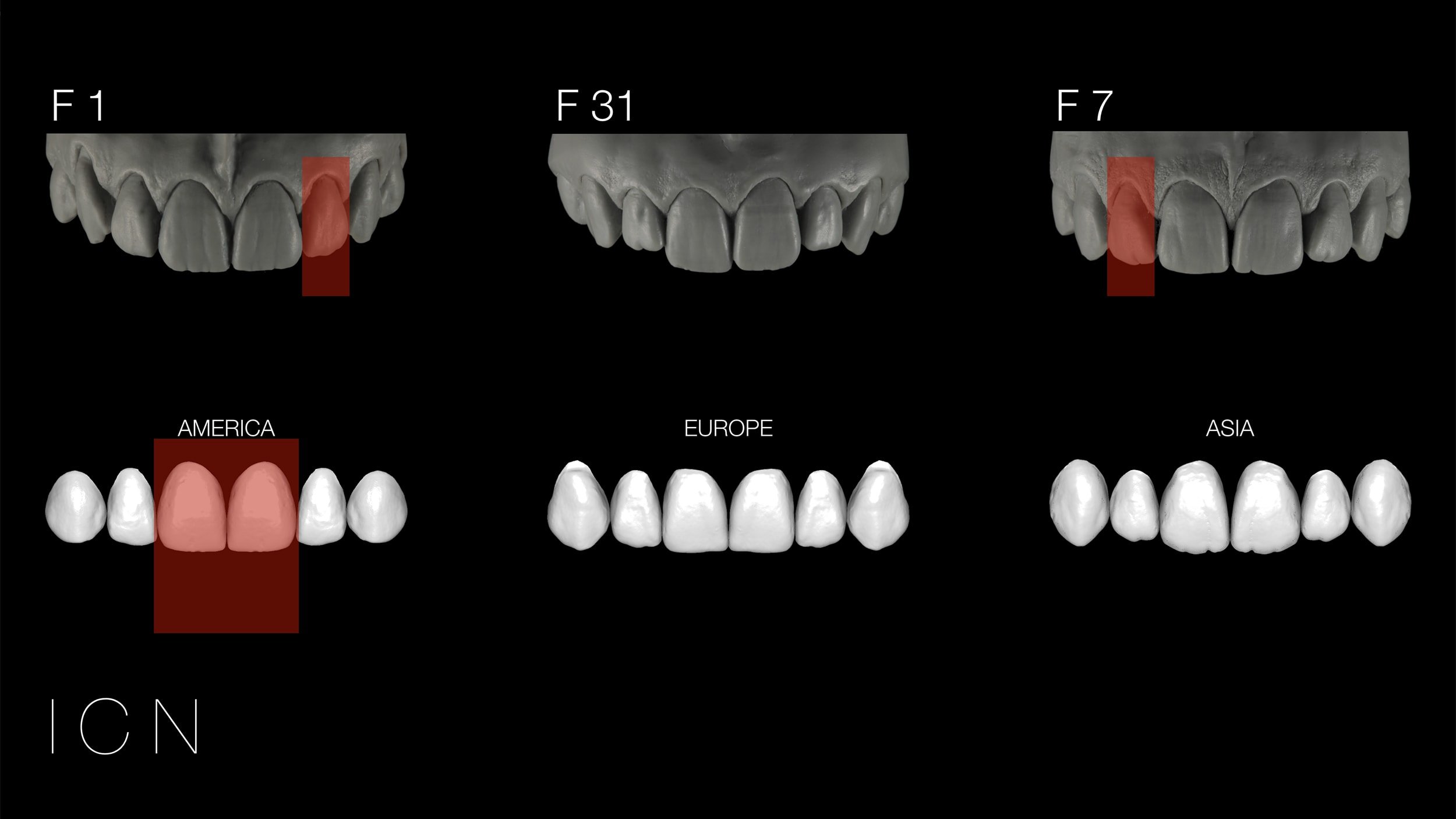

When it’s impossible to copy patient’s teeth we use some other naturally shaped teeth which fit the aesthetic parameters for a specific patient (1st row).

If we’re unable to find the right fit, then we’re using our personal library where we can find something that will fit almost every case in certain combinations and are also made of natural shapes (2nd row).

This kind of system is called ICN (Impulse Copy of Nature).

Wax up is always made digitally, for that way we’re always able to use natural shapes and then we can 3D print it. It cannot be damaged and can be used for an indefinite number of mock-ups.

There are two types of an aesthetic wax up:

1. ‘the realistic’ aesthetic wax up

2. ‘the motivational’ aesthetic wax up

The most demanding wax up is the functional one. Aesthetic and function must be made to appear as realistic as possible. Functional wax up is created as finished work.

Temporary work is also made by using digitally shaped natural looking teeth. In order to create temporary work we use only high-quality material.

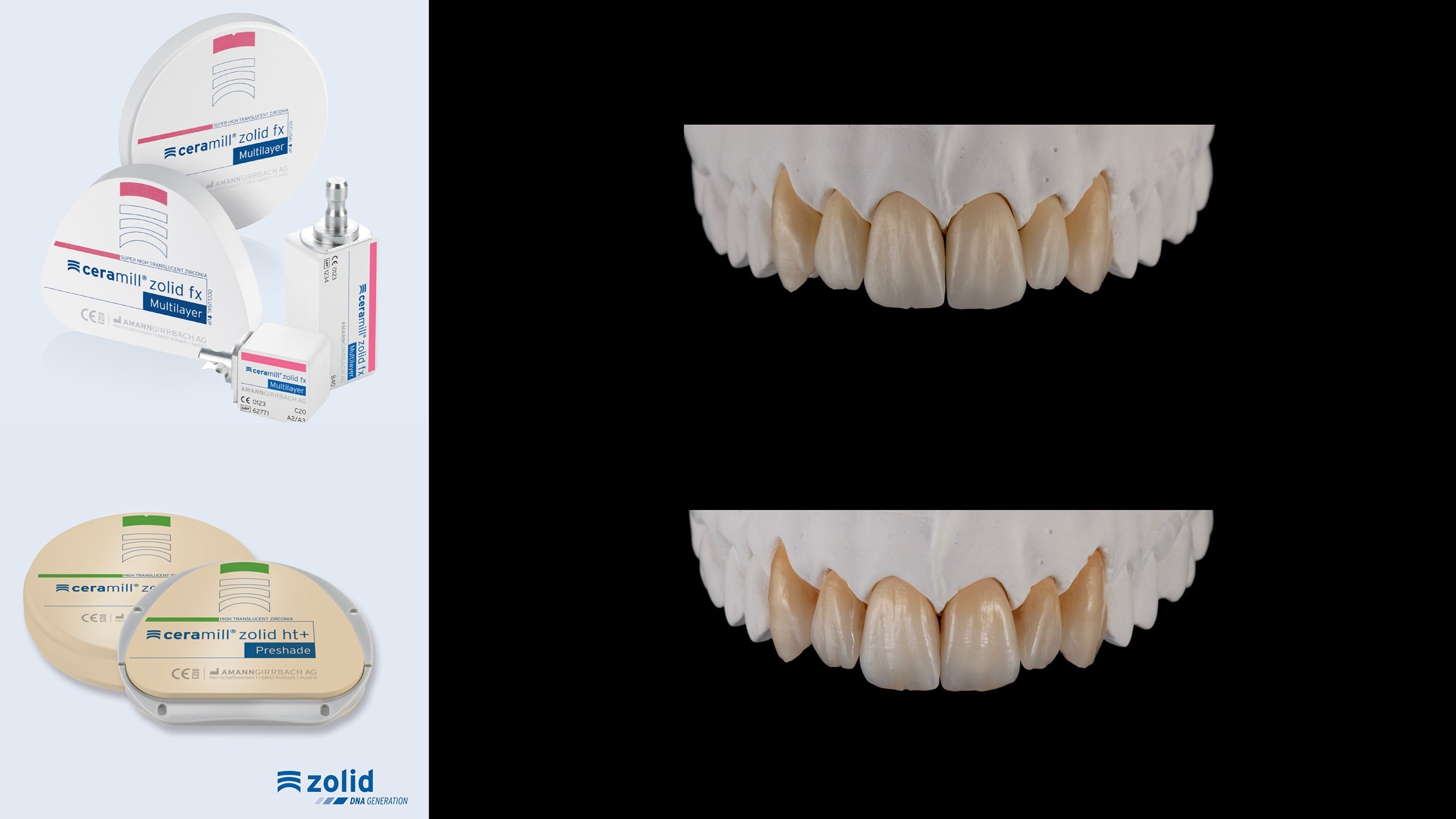

Zirconium material is used as the base to generate 90% of our laboratory work.

Without any exception, we only use high-quality zirconium material from renowned manufacturers with whom we’re also affiliated with as partners.